Screen Printing with Photo Emulsion Sheets

A Dharma Featured Tutorial

Screen Printing is a great way to quickly print a lot of the same design on just about anything but liquid emulsion can be messy. Especially with kids! This is a great way to screen print short runs of a design without the mess, making it much easier to do at home or in a class setting.

Supplies:

- Photo Emulsion Sheets

- Blank Screen - 10"x14"

- Jacquard Professional Screen Printing Ink

- Plastic Glass

- Squeegee

- Acetate Sheets

- Water Bottle with Mist Sprayer

- Tote Bag/Grocery Bag - Carry All Bag #CAB

- Household Iron or professional Heat Press - (unless you use AirFix below)

- Jacquard AirFix - optional

- Carry All Tote Bag

- Exposure Light or Sunlight - we used an old Yudu machine

Let's get started!

Make sure you have a dimly lit area to apply the photo emulsion sheet to the screen and a dark location to let it dry before you get started. The photo emulsion sheets are light sensitive so time is of the essence for this part.

Using the spray bottle, wet the back of the screen as evenly as you can. You don't want it drenched but thoroughly wetted.

Next, take out the emulsion sheets and peel one off the stack, put the rest back in the package for later.

Apply the sheet to the wetted screen with the shiny side up, it is hard to see in photos but there is a clear shiny side which is the plastic sheet the emulsion is carried on. Press the emulsion sheet firmly on the screen and smooth it out with a squeegee.

Flip the screen over to check for any areas that didn't stick/get wet enough, these areas will be sort of white. Spray them with the mist sprayer. One last time press/smooth the emulsion sheet from the back to help it make contact to the screen mesh.

Put your screen into a dark box, closet, etc. to dry. You do not want any light to be able to get in. Let the screen dry for 24 hours.

While the screen is drying prepare your image, print it on to the acetate using a copier or laser printer.

Great Slogans for Bags-

- Thyme to Turnip the Beet

- Kale Yeah!

- A Good Beet

- Don't Kale my Vibe

- Plastic Sucks!

- Totes Mah Goats

- Beyond The Kale

Pro-Tip: To make sure you get a good image on the screen, print two acetate sheets and tape them together to get the ink opaque enough.

Once again, in a dimly lit space-

Take out your screen, carefully pick the corner of the plastic carry sheet up from the emulsion and slowly peel it off. If any emulsion starts to come up then it might not be dry enough, put it back in the dark closet and let it dry. If you have a good dry screen the sheet should peel off and you can discard it or save it to use for some other craft project.

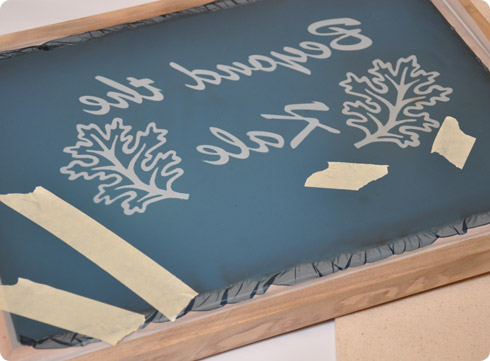

Lay your printed acetate sheet on the screen or on your exposure bed, be sure to flip it so that when you turn the screen over for printing it reads in the right direction!

Lay the plastic glass over the acetate sheet to hold it down. Now, if you are going to take it outside cover everything by slipping it in a black plastic bag, you don't want to start exposing the screen until you are outside.

Pro-Tip: Use a piece of cardboard to help move your screen around before exposing it.

Take the bag off and leave your screen in the sun for about 2 minutes. Watch the emulsion carefully, it will darken from a yellow green to a blue green. That is your sign it is ready! If you are using an exposure bulb, it is generally about 12-14 minutes to expose the emulsion, but every bulb puts out a different wattage so you may want to do a test screen for the first try. If you do over expose the screen use the screen emulsion remover and start again once the screen is clean.

Once you think your emulsion is properly exposed, re-cover everything with the bag and take it to a sink. Remove the bag, acetate sheet and plastic glass. Using cool running water, run the screen under the stream to remove the unexposed emulsion from the screen. It can help to gently rub the screen with your fingertips or use a gentle spray nozzle. DO NOT use a power washer or stiff brush as this may damage the edges of your design.

Once the screen is all rinsed out, put it back out in the sun to dry and fully harden. Now it is ready to print.

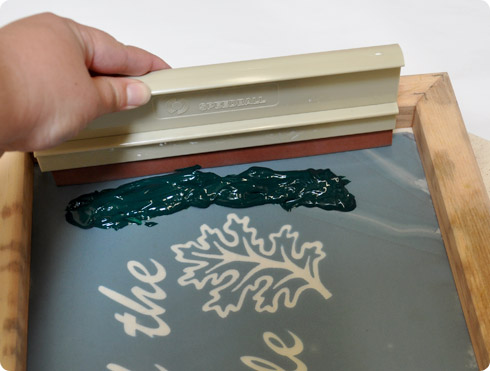

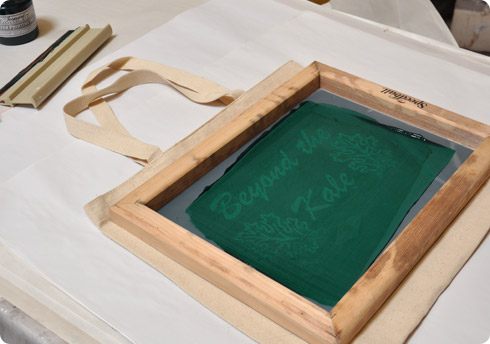

Lay your pre-washed and ironed bag out on your printing table and position the screen. Put a dollop of screen printing ink at the top of the design. We used Jacquard Professional Screen Printing Ink, but you can also use Versatex Printing Ink or Speedball Printing Ink.

Using your squeegee, pull the ink gently but firmly down across the design. This screen is small enough you can hold it down with one hand and pull the squeegee with the other. When you get to the bottom use the squeegee to scoop up the ink and pull it down again from the top of the design. Two passes should be plenty. Gently lift up the screen from one side (like a hinged door), remove your tote and set it aside to dry. One down! Only 100+ to go right?

Once the totes are all dry follow the instructions for heat seating the paint with an iron or heat press.

Pro-Tip: If you mix in some Jacquard AirFix you don't have to worry about heat setting. It cures and makes the paint washable in just a few days. :-)

If folks in your grocery line ask where you got 'em, tell them you'll make them some! You have the screen(s) made already, might as well turn them to cash!

Written and Photographed by Elizabeth Holdmann for Dharma Trading Co.