Shopping list:

- Speedball Screenprinting Kit

- Piece of Glass

- 4 Pushpins

- A Piece of black fabric

- Versatex Screenprinting Ink - (if you want colors other than the ones included in the kit)

- A sturdy board or piece of cardboard/foamboard

Let's get started!

This is a new little Matroyska screen print that I designed for some dresses. I just love her! I took some photos of the process I used because I think it is so easy and efficient and I know you all would love doing it. This would be a great way to make Christmas presents for the whole family! I'm making t-shirts for gifts! Also many of you often ask me where I get the cute t-shirts I use for dresses....I often make them and you can too....

I used this Speedball Screenprinting kit from Dharma Trading which included almost everything I needed. There are several methods included in the kit: screen filler method, drawing fluid method, and photo emulsion.

The photo emulsion method usually scares people off but it produces the most amazing results because you can do such detailed images (thin lines, small text, etc.). I've tried to break it down here into the most basic of steps and without the fancy lingo:

Just a quick simple explanation of how the the photo emulsion process works:

Basically I think of it as film. You use light to expose an image onto the screen to make a stencil. The photo emulsion hardens where light hits it and will wash away where light doesn't hit it (leaving an image behind). Note: I use natural sunlight for my light source. It is best to wait until the sun is high in the sky (i.e. around noon).

Step 1: Creating an Image

I designed my little Matryoshka doll in Powerpoint of all things (I don't have a graphics program) using basic shapes and dingbat fonts....just overlapping white and black shapes. I've included a few images at the bottom of the post and I'll be designing a few more just for you over the next few weeks.

Step 2: Printing A Transparency

Print 2-3 copies of your image to a transparency. I don't have the best printer so I save my image to a disk and take it to Kinko's and have them print the transparency for me.....the transparencies run about 75 cents a piece.....they are also much crisper printed from a commercial laser printer! Stack each of the transparencies on top of each other to create a complete "blackout" of the image....I use a little tape on the corners to keep them together.

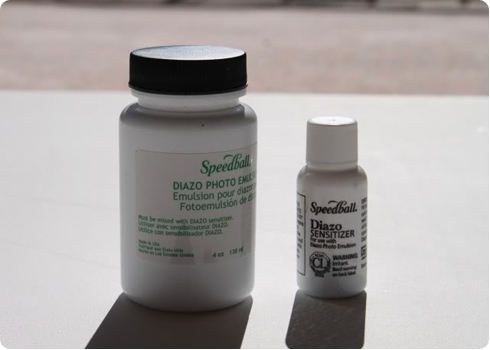

Step 3: Mixing the Photo Emulsion

The kit has a large bottle of photo emulsion and a small bottle of sensitizer. Follow the directions but basically you add water to the sensitizer and mix it up. This process is a little tedious because the residue in the bottle is coagulated at the bottom....I used a small clean paint brush to mix it so I could "swish" the residue off the bottom.

Mix the sensitizer (black liquid) into the photo emulsion bottle (bluish liquid) until the mixed liquid becomes a slime green color:

Step 4: Prepare the Screen

The bottom of your screen is the non-recessed part (i.e. the screen is flush with the bottom of the frame). Turn your screen so the bottom part is facing up and insert a pushpin into each corner. This will help with the next step of spreading the emulsion (and provide little "legs" for your screen to sit on while it dries).

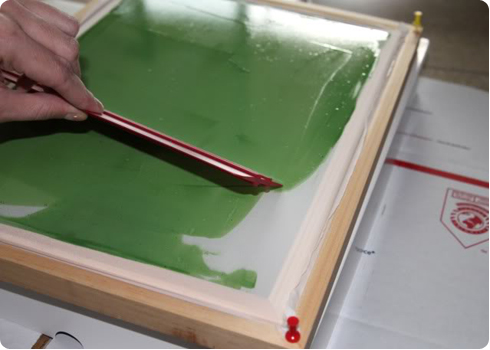

Step 5: Applying Photo Emulsion to the Screen

You will want to do this step in a fairly dim room since the photo emulsion reacts to light. Spread a small amount of the photo emulsion on one side of the screen bottom......

......and use the squeegee from your kit to spread a thin layer of the emulsion across the screen. Flip the screen over and repeat on the other side.....

....and keep spreading and flipping until you have a thin even layer across the entire screen.

Place your finished screen right side up (the pushpins will serve as little legs) in a cool dark place for a few hours or overnight to let it dry. I carefully placed mine back in the original box bottom to protect it.

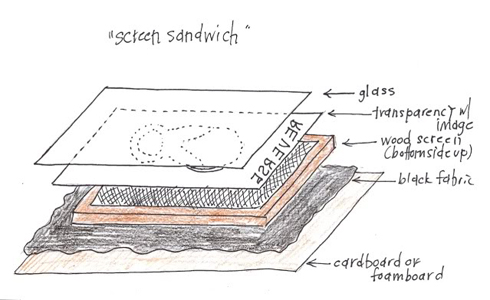

Step 5: Preparing the Screen for Exposure

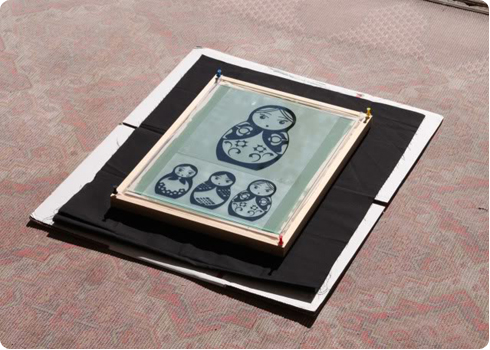

Once your screen is dry you are ready for the "exposure" part. As soon as you are ready to go (with no distractions), take your screen out of its cool dark place (but still in a dim area) and remove the pushpins. Assemble what I call the "screen sandwich" which is a sturdy piece of cardboard (so you can carry the screen into the sun easily), followed by a piece of black fabric to reduce reflection, the prepared wood screen (bottom side up), the transparencies (face down), and finally a piece of glass to hold your image in place against the screen.

Step 6: Exposing the Screen

Note: I use natural sunlight for my light source. It is best to wait until the sun is high in the sky (i.e. around noon) so the light is direct. See the bottom of the post for links using artificial light.

Cover your "screen sandwich" with a piece of cardboard or paper and carefully carry it outside into the direct sunlight. This is the tricky part because if you expose the screen for too long it will burn the image into place and it won't wash away.....and if you don't expose it long enough areas of the image might wash away. Here is how I gauge the exposure: the emulsion is a slime green color and as it exposes it begins to turn to a dark gray/green. Once you see it darken considerably it has been exposed....it should only take 2-3 minutes depending on how strong the sun it. If it is overcast it may take a few more minutes.

Carry the "screen sandwich" back inside quickly and remove the glass and transparency and take the screen directly to the sink. Your image should still be a slime green color and the rest of the screen will be the dark gray/green.

Step 7: Washing the Screen

Using a sprayer or hose apply a forceful stream of water to the screen. After a few minutes the screen will start to open up and the image areas will start washing away leaving your "stencil." If the areas do not wash away you may have overexposed the screen....and you will need to use the "emulsion remover" from the kit to clean the screen and start the process over......exposing it for much less time.

Step 8: Printing

Hold your dry screen up to the light to see if there are any holes......and use the screen filler included in your kit to touch them up. Use painting tape to cover all the inside edges of your screen to prevent any ink from leaking through.

Cover your work area and get your ink and squeegee ready.

Place your screen flat onto the fabric that you are preparing to print (if it is a t-shirt make sure to place a piece of cardboard inside to prevent ink from soaking to the other side). Apply a small glob of ink at the top of side of the image.....

....and pull the ink down the screen with the squeegee. You might have missed some areas so I like to go over it a few times carefully. Do a test run to get the hang of it before printing on your nice t-shirt!

Carefully remove the screen and admire your image!

Step 9: Heat Setting the Ink

Allow the image to dry and then heat set according to your ink directions (usually just ironing on a high setting for several minutes).

Feel free to email me with questions!

Here are some other links you might find useful:

How to use artificial light for exposure (instead of sunlight)

Below are a images ready to download and you are welcome to use. Just right click and save to your desktop (or click and drag to your desktop on a Mac) and burn to a CD to take to your local Kinko's printer.

Mr. and Mrs. Robot:

Copyright © 2009 by Ashley Hackshaw. All rights reserved. This robot template is for personal and home use only. Thank you for respecting my copyright! Please email me if you have questions about use of this image.

These images are from a Pixel Farms' font Pets and I LOVE them: